Pfizer, GSK, GEA and G-CON Manufacturing - Getting Medicines to Patients Faster

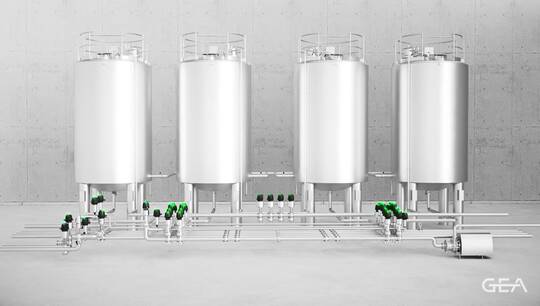

PCMM’s potential for smaller, more flexible, continuous processing technologies include a 60–70% smaller footprint than a conventional production facility, the ability to use the same equipment for development, clinical trials and commercial manufacturing, and significantly reduced timelines: a PCMM (portable, continuous, miniature and modular) facility takes about a year to set-up and start running compared with 2–3 years for standard processes.

With PCMM, the partners are leading the way toward smaller, more flexible, continuous processing technologies with the potential to transform the future of pharmaceutical development and manufacturing, and deliver customized quantities of drugs to patients in need in a quick and efficient way.

(Curtesy of Pfizer)