Finding the right mixproof valve for your application - from hygienic to aseptic webinar

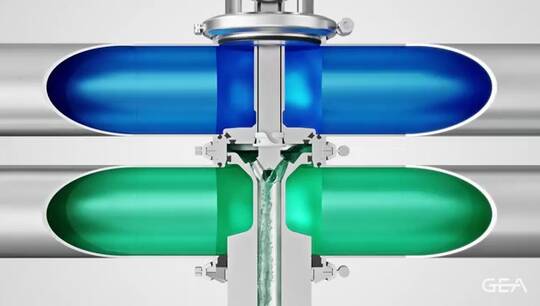

In processing plants that focus on ESL (extended shelf-life), UltraClean and aseptic applications, both the valve/piping design implementation and the valve matrix configurations are unlike those utilized with hygienic applications. When dealing with highly specialized applications it is critical to optimize process performance and maintain strict product standards by eliminating cross-contamination potential. At the same time, the technology must make economic sense.

This webinar will help you gain an understanding of the technical features, advantages and benefits of double-seat valves, particularly as they apply to ESL, UltraClean and aseptic processes.

The webinar covers the following:

- Risks of product contamination due to the “elevator effect”

- Hygienic mixproof valves with sterile locks

- Valves with an integrated steam barrier (ISB) which enable the safe separation of product lines with a sterile media

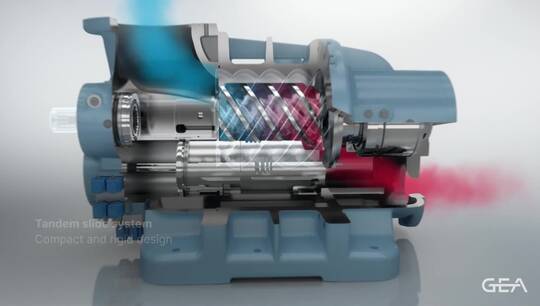

- Hermetic sealing with PTFE stem diaphragms or stainless-steel bellows

- Use of double-chamber valves or selecting valves with multiple sterile chambers for ultimate process flexibility

- Installation and service requirements for each technology

- Areas of application