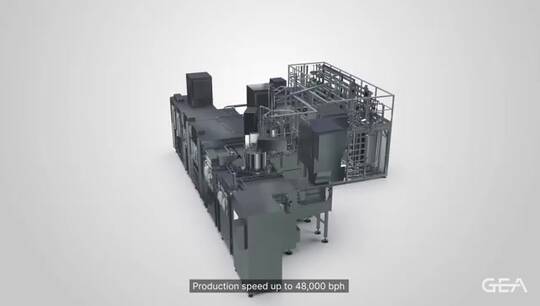

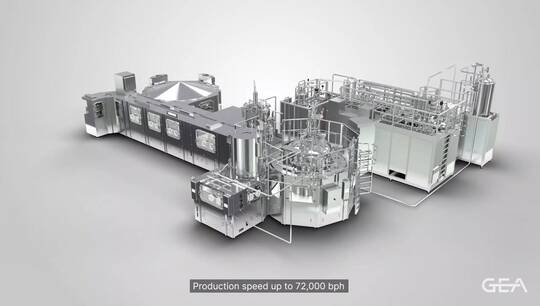

GEA Beverage - ABF now running at 48.000 bph

Come inside the fastest ABF now running at 48.000 bph. ABF is the world’s first rotary aseptic blow moulding machine with an integrated aseptic filler and capper. The principle is to sterilize the preform with Hydrogen Peroxide at the exit of the oven; then blow the preforms with sterile air in a sterile environment and maintain this sterility throughout the filling and capping process.