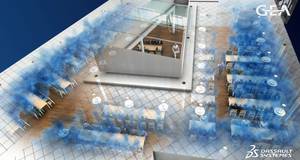

Digital twin used to simulate the spread of aerosols at GEA site

Given aerosols help spread COVID-19, GEA was keen to know how it would spread through airflows and via the HVAC systems in the cafeteria at its Oelde site. Partner Dassault Systèmes tested various scenarios using digital twin, or simulation technology. The results will inform GEA's health and safety procedures ahead of the reopening of this and other GEA cafeterias.