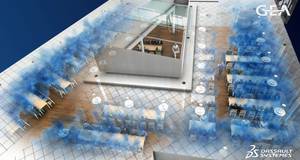

Digitaler Zwilling simuliert Aerosol-Verteilung bei GEA

Unter welchen Umständen können wichtige Räumlichkeiten von Unternehmen wie Kantinen wieder sicher geöffnet werden? Das arbeitet GEA derzeit am Standort in Oelde für mehr als 1.900 Mitarbeiter aus. Ein Digitaler Zwilling, konzipiert vom Softwarepartner Dassault Systèmes, wird dabei zum wichtigen Puzzleteil. Er simuliert den kompletten Kantinenbetrieb und die Aerosol-Verteilung im Raum, was zu wertvollen Erkenntnissen für die Erarbeitung entsprechender Hygienekonzepte führte.